Who knew?

Eric Keibler Apr 02, 2008

Have you ever been surprised when you finally meet someone you have had an email relationship with? Well if you have, you would understand my surprise at visiting the Delta P/CCR Technologies offices in England.

We have sold the VR3’s in our store since its introduction a long time ago. I have had a long distance relationship with them for all of those years – mostly by email, telephone and an occasional meeting somewhere in the US. So when I visited their offices recently, I was surprised at what I found.

First of all, they are out in the country. Well sort of, their office is in an small business park outside of Poole, that is out away from the city, port and hustle of Poole. When I went upstairs to meet Al and Kevin I found a staff of 7 in the office including Kevin Gurr, the president of the Company, Jason the lead engineer and designer, Freda from customer service, Mandy in charge of production and procurement, Chris in customer service and billing, Linda, in charge of accounting and of course Al who is the primary client services person and one of the go to people at Delta P.

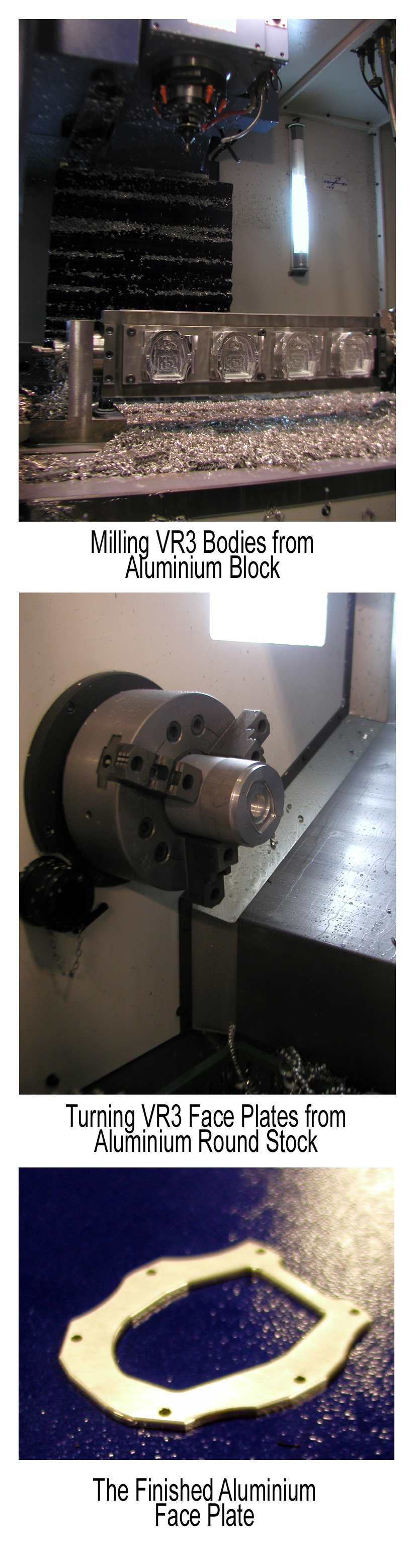

After tea, Jason took me on a tour of the facility. Our first stop was actually to the building next door where Jason introduced me to Steve, the Production Manager He is an amazing person; he has 28 years of aircraft parts fabrication experience and heads up the thing that surprised me the most about my visit, the production facility. Unlike many small scuba manufacturers, Delta P actually builds the cases for their computers as well as the majority of the components for both the Sentinel and Oroborus Rebreathers. They have two C&C Mills and two C&C lathes along with one off manufacturing machinery and tools.

My assumption was that they had the components built to their specifications and then assembled the products. In talking to Jason and Kevin., having your own production facility is the only way to control the quality of your product. The production facility was impressive. The operators were all hired away from the aircraft industry and had 10 to 15 years of experience in that industry prior to joining Delta P.

It was interesting to see all of the parts, both aluminium and plastic. The plastic parts on the rebreathers are not injection molded plastics but rather milled from Delrin stock. Some of the operations take 48 to 72 hours to complete – isn’t automation wonderful?

Steve is passionate about his work and he is proud of the products they build. The milling is precise, the finished parts are clean and free of manufacturing debris. All of the employees in the production unit, are very proud of their work and volunteered to show me what they were doing, how it was being done and what the finished product would look like.

Our next stop on the tour was the shipping department and then on to the assembly room. Here I met Richard who was assembling Sentinel sub-assembly parts preparing for the next build cycle for the Sentinel rebreathers and the upcoming ISO 9001 compliance audit. Here were Poseidon regulators being fitted with adapters for the hoses, manifold blocks with hoses being attached and heads assembled in the electrical shop (our next shop). They currently have three assembly stations but have plans on adding more to help meet the demand for the new Sentinel rebreather. According to Kevin, they have over 100 on order at this time.

After tea, they drink a lot of tea here, my tour continued on to the electrical department, currently housed in a temporary building next to the main building. There are 4 people working here assembling both the Sentinel rebreather heads and the dive computers. Additionally, they handle repairs and health checksfor customer computers and rebreather heads. Besides the things you would normally expect in an electrical assembly department (wire, solder, soldering irons, parts, etc) there were two different pressure pots. One unit is for testing the rebreather components and the other is for the VR3 and VR2 computers. Before they leave the electrical department, every component is pressure tested.

My tour was a complete surprise and impressed me at the same time. Here is a Company that has invested heavily in manufacturing and technology in order to build a product that they are proud selling and diving. Since most of the staff are divers, they carry the passion they have for their sport into their jobs.